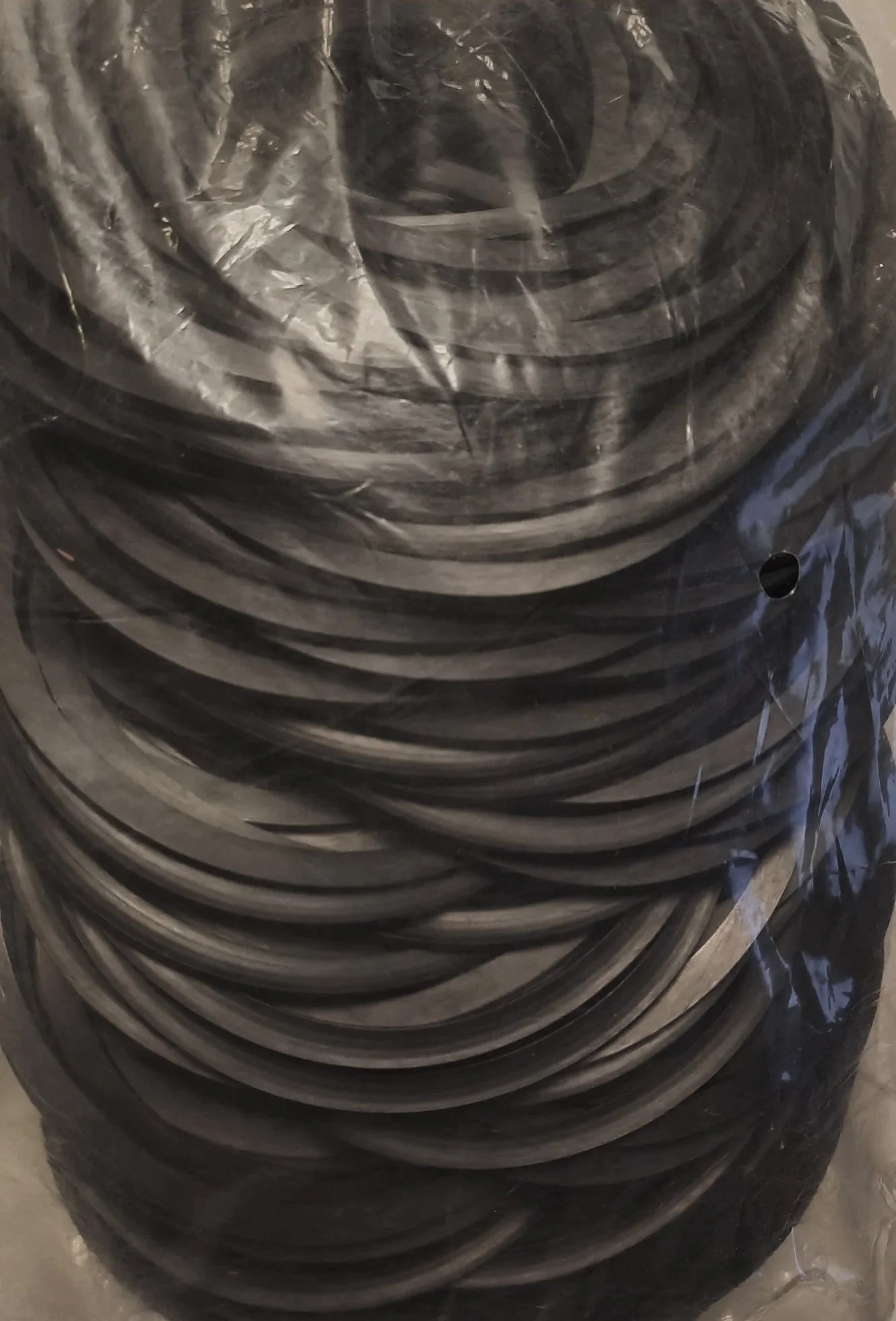

Back up (BUR) for O'ring 342 NBR 90A

Back-Up O-ring 342 — NBR 90A

Description A back-up O-ring manufactured from Nitrile Butadiene Rubber (NBR) with a hardness of 90 Shore A. Designed to be used as a support element in sealing assemblies to prevent extrusion of primary O-rings in high-pressure or dynamic applications. Back-up O-ring 342 offers excellent compression resistance, good wear properties, and reliable dimensional stability over repeated cycles.

Key Features

Material: NBR (Nitrile Butadiene Rubber)

Hardness: 90 Shore A

Function: Anti-extrusion / back-up support for primary O-rings

Typical uses: Hydraulic cylinders, high-pressure static and dynamic seals, valve stems, and pump housings

Temperature range: approximately -20°C to +100°C (-4°F to +212°F) depending on service conditions

Chemical compatibility: Good resistance to petroleum-based oils, fuels, and hydraulic fluids; limited resistance to ketones, strong acids, and aromatic hydrocarbons

Benefits: Prevents extrusion of softer O-rings, extends seal life, improves reliability under high pressure and tight gland tolerances

Typical Dimensions and Installation Back-up rings are typically used in pairs (one on each side of the primary O-ring) and are available in a range of internal/external diameters and cross-sections to match standard O-ring sizes. Installation should ensure correct orientation if using asymmetric profiles and sufficient gland clearance to avoid cutting or rolling of the back-up ring.

Selection Notes

Match the back-up ring size to the gland and primary O-ring cross-section.

Use 90A hardness NBR where high rigidity is needed and fluid compatibility is primarily petroleum-based.

For higher temperature or chemical resistance, consider alternative materials (e.g., PTFE, FKM, or polyurethane).

Confirm operating pressure, temperature, and media to ensure appropriate performance.

Storage and Handling Store in a cool, dry place away from direct sunlight and ozone sources. Avoid contact with solvents or oils not compatible with NBR prior to installation.

Back-Up O-ring 342 — NBR 90A

Description A back-up O-ring manufactured from Nitrile Butadiene Rubber (NBR) with a hardness of 90 Shore A. Designed to be used as a support element in sealing assemblies to prevent extrusion of primary O-rings in high-pressure or dynamic applications. Back-up O-ring 342 offers excellent compression resistance, good wear properties, and reliable dimensional stability over repeated cycles.

Key Features

Material: NBR (Nitrile Butadiene Rubber)

Hardness: 90 Shore A

Function: Anti-extrusion / back-up support for primary O-rings

Typical uses: Hydraulic cylinders, high-pressure static and dynamic seals, valve stems, and pump housings

Temperature range: approximately -20°C to +100°C (-4°F to +212°F) depending on service conditions

Chemical compatibility: Good resistance to petroleum-based oils, fuels, and hydraulic fluids; limited resistance to ketones, strong acids, and aromatic hydrocarbons

Benefits: Prevents extrusion of softer O-rings, extends seal life, improves reliability under high pressure and tight gland tolerances

Typical Dimensions and Installation Back-up rings are typically used in pairs (one on each side of the primary O-ring) and are available in a range of internal/external diameters and cross-sections to match standard O-ring sizes. Installation should ensure correct orientation if using asymmetric profiles and sufficient gland clearance to avoid cutting or rolling of the back-up ring.

Selection Notes

Match the back-up ring size to the gland and primary O-ring cross-section.

Use 90A hardness NBR where high rigidity is needed and fluid compatibility is primarily petroleum-based.

For higher temperature or chemical resistance, consider alternative materials (e.g., PTFE, FKM, or polyurethane).

Confirm operating pressure, temperature, and media to ensure appropriate performance.

Storage and Handling Store in a cool, dry place away from direct sunlight and ozone sources. Avoid contact with solvents or oils not compatible with NBR prior to installation.