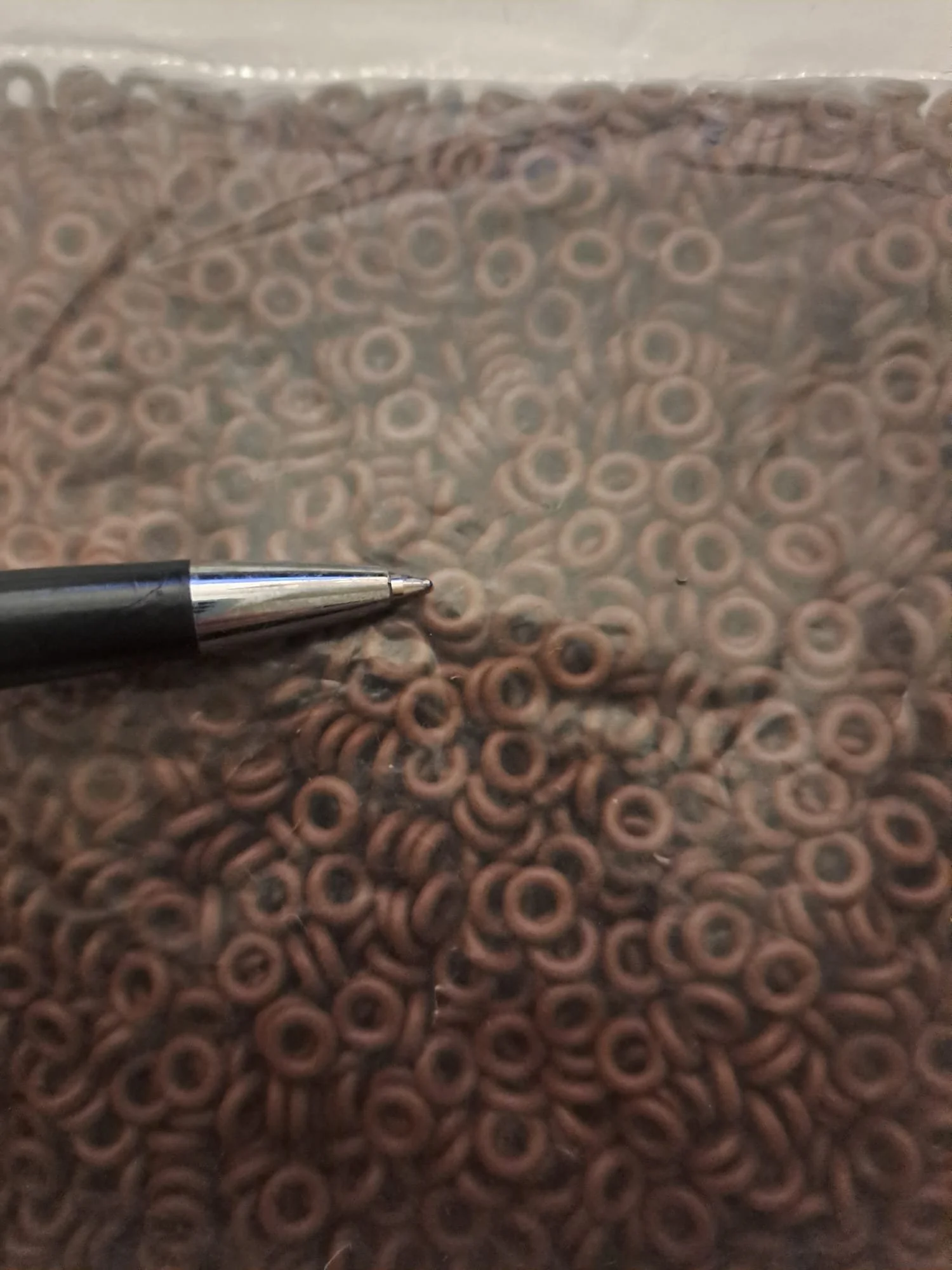

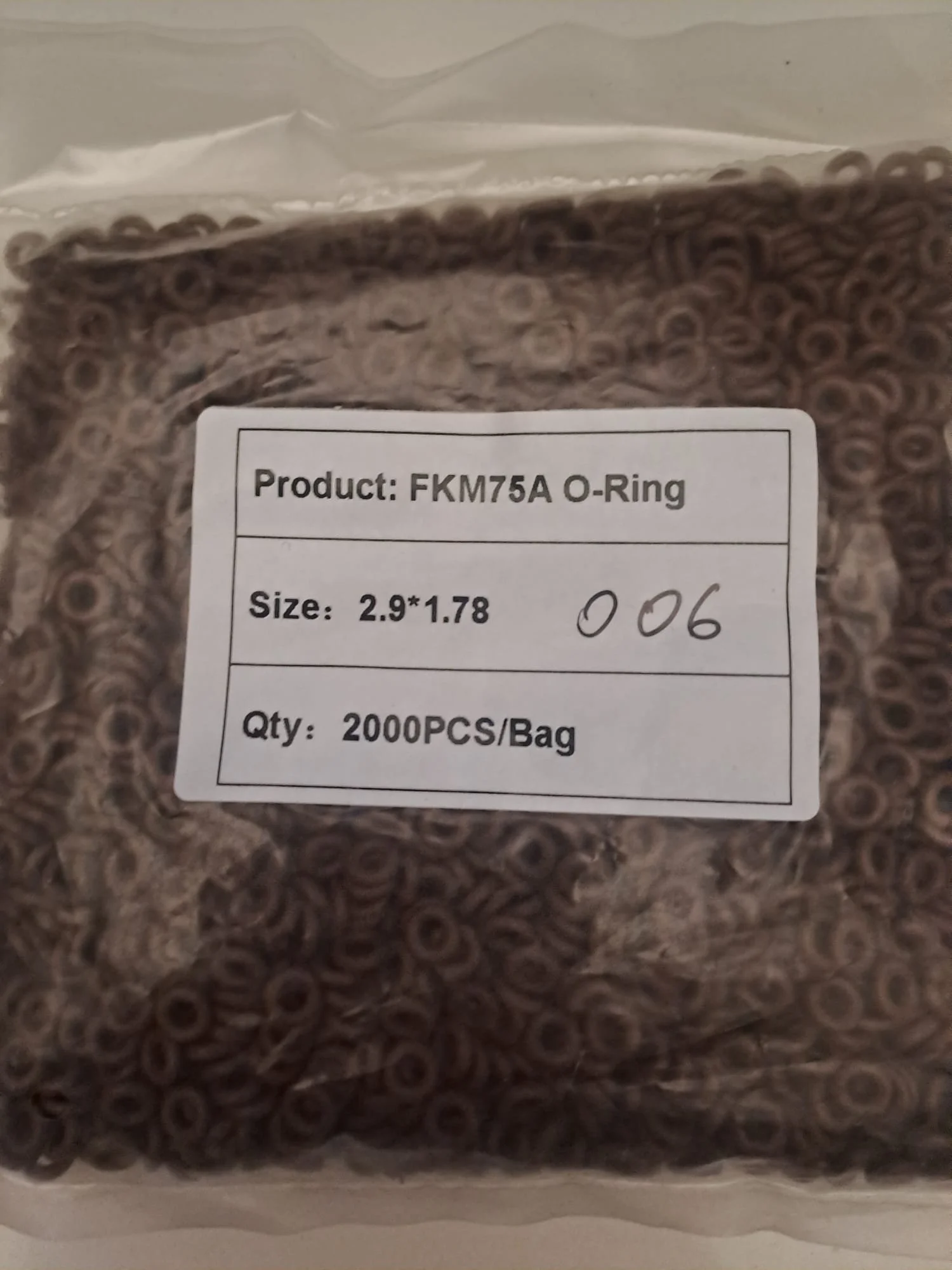

O'ring 006 V 75A 2.90±0.13 1.78±0.08

FKM 75 A (Viton 75) O-ring — Available Q4 2025 stock or by Order

Product overview

Material: FKM (Viton® 75) — fluorocarbon elastomer, 75 Shore A hardness

Common applications: high-temperature sealing, automotive fuel systems, hydraulic systems, chemical processing, HVAC, oil and gas

Key properties: excellent resistance to fuels, oils, hydraulic fluids, silicone fluids, aromatic and chlorinated hydrocarbons; good compression set resistance; continuous service temperature range typically −20°C to +200°C (short excursions higher)

Stock and lead times

In stock: Manufactured and available from Q4 2025

By order: Available on request for custom sizes or quantities; lead time depends on order volume and tooling requirements (typicaly 1–4 weeks)

Standard sizes and specifications

Sizes: Available in common AS568 (SAE) sizes and metric cross-sections; custom IDs and cross-sections on request

Hardness: 75 ±5 Shore A

Certifications: Material meets typical FKM/Viton quality standards; certification packages (material test report, RoHS, REACH) available upon request

Color: Standard black for NBR, red for Viton; other colors available by special order

Performance and compatibility notes

Chemical resistance: Excellent to hydrocarbons, motor fuels, and many chemicals; consult chemical compatibility data for specific media (some ketones and strong amines can attack FKM)

Temperature: Suitable for continuous use up to ~200°C; low-temperature flexibility decreases below −20°C

Compression set: Good resistance at elevated temperatures compared with many elastomers

Not recommended for: Strong bases, ketones (e.g., acetone), some ester-containing fluids, or prolonged exposure to steam without validation

Ordering information

Minimum order quantity: Varies by size and whether standard stock is used; contact sales for exact MOQ

Packaging: Bulk, bagged, or custom packaging options available

Pricing: Available upon request; volume discounts apply

Lead time for stocked items (Q4 2025 stock): Immediate dispatch from Q4 2025 inventory

Lead time for made-to-order: Typically 1–3 weeks depending on size, quantity.

Quality and traceability

Manufactured to industry standards with batch traceability

Certificates available: Material test reports, dimensional inspection, and regulatory compliance documentation on request

How to order

Provide: Part number or AS568/metric size, quantity, required certifications, and desired delivery date

For custom requests: Specify ID, cross-section, material, hardness (if different), and any special processing (e.g., secondary operations, special packaging)

Contact sales with your size, quantity, and delivery requirements to confirm availability from Q4 2025 or place a made-to-order request.

FKM 75 A (Viton 75) O-ring — Available Q4 2025 stock or by Order

Product overview

Material: FKM (Viton® 75) — fluorocarbon elastomer, 75 Shore A hardness

Common applications: high-temperature sealing, automotive fuel systems, hydraulic systems, chemical processing, HVAC, oil and gas

Key properties: excellent resistance to fuels, oils, hydraulic fluids, silicone fluids, aromatic and chlorinated hydrocarbons; good compression set resistance; continuous service temperature range typically −20°C to +200°C (short excursions higher)

Stock and lead times

In stock: Manufactured and available from Q4 2025

By order: Available on request for custom sizes or quantities; lead time depends on order volume and tooling requirements (typicaly 1–4 weeks)

Standard sizes and specifications

Sizes: Available in common AS568 (SAE) sizes and metric cross-sections; custom IDs and cross-sections on request

Hardness: 75 ±5 Shore A

Certifications: Material meets typical FKM/Viton quality standards; certification packages (material test report, RoHS, REACH) available upon request

Color: Standard black for NBR, red for Viton; other colors available by special order

Performance and compatibility notes

Chemical resistance: Excellent to hydrocarbons, motor fuels, and many chemicals; consult chemical compatibility data for specific media (some ketones and strong amines can attack FKM)

Temperature: Suitable for continuous use up to ~200°C; low-temperature flexibility decreases below −20°C

Compression set: Good resistance at elevated temperatures compared with many elastomers

Not recommended for: Strong bases, ketones (e.g., acetone), some ester-containing fluids, or prolonged exposure to steam without validation

Ordering information

Minimum order quantity: Varies by size and whether standard stock is used; contact sales for exact MOQ

Packaging: Bulk, bagged, or custom packaging options available

Pricing: Available upon request; volume discounts apply

Lead time for stocked items (Q4 2025 stock): Immediate dispatch from Q4 2025 inventory

Lead time for made-to-order: Typically 1–3 weeks depending on size, quantity.

Quality and traceability

Manufactured to industry standards with batch traceability

Certificates available: Material test reports, dimensional inspection, and regulatory compliance documentation on request

How to order

Provide: Part number or AS568/metric size, quantity, required certifications, and desired delivery date

For custom requests: Specify ID, cross-section, material, hardness (if different), and any special processing (e.g., secondary operations, special packaging)

Contact sales with your size, quantity, and delivery requirements to confirm availability from Q4 2025 or place a made-to-order request.